Senior Projects

Skid Steer

The purpose of this project is to design and execute the construction of a mini Skid Steer. The ability to successfully accomplish their capstone as a group of engineers was to further their abilities in industry. Another goal was to provide a solution to heavy snow fall in Utah. Some of their major goals were to stay within the budget of $6,000, fabricate the project, meet all welding code requirements, and complete the project on time.

Weber Wobbler

The mission is to build a wobble base for an automatic clay pigeon thrower. We wanted the wobbler to randomize the trajectory of the targets, and to build it for less than the current product available on the market.

Inconel welding

*Inconel is the brand name for a group of specific nickel-chromium alloys. These alloys are most often used in applications that require a high tolerance for heat. Inconel is generally difficult to weld because the welds have a tendency to crack. However, a few alloys of Inconel are designed specifically to be weldable. Inconel is often welded with titanium inert gas (TIG) welding. (Source: http://classroom.synonym.com/weld-inconel-2396.html)

The main purpose of this senior project was to study and develop welding programs and to determine the weldability of Inconel 718. To accomplish this they used the Miller Auto access 450, Bug –O track system, metallographic equipment, Panasonic robotic system and tooling designed to shield the molten weld pool on the backside of the part. With the conglomeration of all these systems they attempted to weld Inconel 718 with zero defects in the same spot each and every time.

Boeing Box washer

Watch Video on Youtube

The project scope, as described by Boeing, was to design and manufacture of an apparatus to uniformly clean and rinse the entire length of each chamber. The apparatus was to be installed in Boeing’s West Jordan, UT facility. The apparatus must be motion-capable in order to align directly in front of each chamber, as well as vacating the opening entirely to allow for a fan array to be placed in front of the root end.

Current process cycle time is approximately eight hours. Target cycle time for apparatus is approximately two hours. Other target specs include: single operator capability, operating PSI of 180, air blade capability, and sufficient shielding for operator.

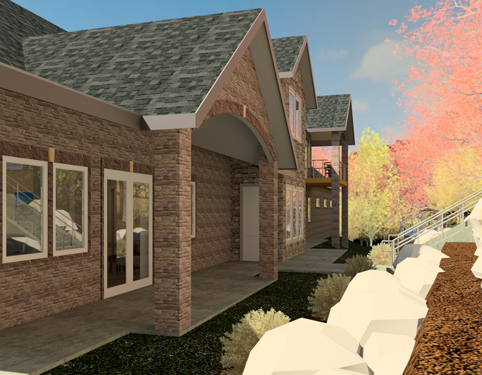

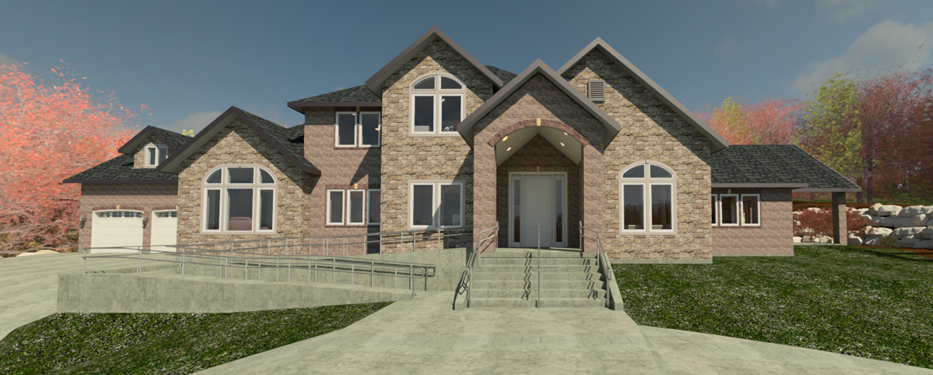

Presidential Designs

Anytime Weber State University chooses a new president, one of the major challenges is providing housing for the president and his family. The role was to work and collaborate with the president of the University, Facilities Management, and other members of Weber State to design a home. The home incorporates universal design principles that will meet the needs of the current president and all other presidents to come. The home is to be designed to incorporate both a private living area for the President and his family, and a public gathering area for events and special occasions. The separation of these two areas is what drove the design. The home utilizes the front entry as the separation between the private and public areas. The private area is designed to feel like a traditional home, and the public area has been designed to be ADA accessible, have a full catering kitchen and a large gathering room.