Kelly Harward

Professor, Manufacturing Engineering Technology 1979 – 1981 & 1987 - present

History of CAD/CAM at Weber State

In 1978, Weber State sent a request for proposal and quote to five companies for a Computer-Aided Design/Computer-Aided Manufacturing System. These five companies, leaders in the CAD/CAM industry at the time, were Applicon, Computer-Vision, Calma, Intergraph, and AutoTrol. Weber State decided to purchase a 2-workstation system from Applicon for just under $100K. During this time before the advent of the personal computer or the development of CAD/CAM software on stand-alone workstations, CAD systems were mainframe based or mini-mainframe based systems with CRT’s or terminals connected to the CPU of the mainframe computer.

I worked for Applicon out of their SLC office and was assigned as a Systems Engineer to support Weber State with initial training and implementation of their system. The Applicon CAD system WSU purchased included a Digital Equipment PDP-11 computer with a Memorex disk drive with about 30 Mbytes of Storage. These components made up the main control unit and were installed in the Engineering Technology building room ET124. The two workstations were installed next door in room ET 120. I conducted several training sessions with Professors’ Roy Thornock, and Bob Wallentine from the Manufacturing Engineering Technology Department and Professor Almond from the Electronics Engineering Department. After the initial training sessions during the summer of 1979, Professor Thornock, asked me if I would be interested in teaching WSU students during that Fall Term. I worked out a schedule with Applicon that allowed me to teach as an adjunct during that first term. WSU and the MfET department helped me hire two student lab aids, Michael Lyon and Paul Cook, both senior students in the MfET program. The Applicon CAD system was scheduled 24-7 so students could have a few hours each week to complete their assignments. Students were usually able to get a couple hours each week during the daylight hours but most everyone also had to schedule a couple hours after 10pm and before 6am each week in order to complete their assignments.

Figure 1:Applicon CAD/CAM System, Circa 1978

This initial CAD/CAM system was soon outdated after just a couple of years and WSU attempted to use a larger system based on a mainframe computer. The 2D CAD system software ran on the university’s Prime computer with a few workstations in our ET building. This attempt was wholly unsuccessful because of the slow response time at the workstations for the students and the lack of software capability.

In 1986, WSU’s MfET department was able to purchase a used, larger Applicon system with 4 workstations and a large digitizing tablet and installed this system in ET 103. The MfET department hired Larry Leavitt to implement a more functional CAD/CAM system while I, from Applicon, continued to support Weber State. In 1987 with the classes now being offered in both the MfET and the DET programs, WSU also hired me as a full-time instructor.

In 1989, WSU purchased 10 IBM PCs running DOC operating system and the AutoCAD software. This low-end CAD systems had some of the high-end mainframe-based CAD systems but were much more affordable allowing WSU to purchase a number of PCs and so students did not have to use the lab after midnight and before 6am. During this time, Larry Leavitt implemented MasterCAM as the CAM software to use the CAD data for creating tool-path geometry and G-codes to run the CNC machines.

As the software improved and the cost of PCs became even more affordable, WSU expanded the CAD lab to 20 PCs. WSU also acquired educational licenses of other CAD software such as Anvil2000, CADsIV (ComputerVison), and CADKey all of which ran on the DOS-based PCs. Yet, these PC-based CAD systems did not have all the functionality of the higher-end systems. Some of the higher end systems now ran on stand-alone workstations such as the Silicon Graphics. Larry Leavitt, Kerry Tobin, and I solicited grants from SME and NSF for to purchase additional CAD/CAM and automation equipment. Some of these grants were used to fund the purchase of several Silicon Graphics workstations.

Larry Leavitt and I installed the IDEAS CAD software from Structural Dynamics Research Corporation, along with Catia and CAEDs(Dassault Systems) on the high-end workstations. The challenge with this configuration of computer hardware was the maintenance of the systems. During this time, we had an in-house computer support man, Cliff Peterson, who worked for the college (maybe school at the time) and an occasional help from an IT guru from the university. The workstations operating system was UNIX, the mainframe computer on campus ran OS, and the PCs ran DOS. Creating the interfaces between the systems for an integrated (or interfaced) CAD/CAM system was always a challenge and very time consuming. Due to the limited IT resources at the university, Larry Leavitt and I worked many late nights over several semesters installing hardware and software, debugging and configuring the systems in order to have a functional CAD/CAM system for their classes.

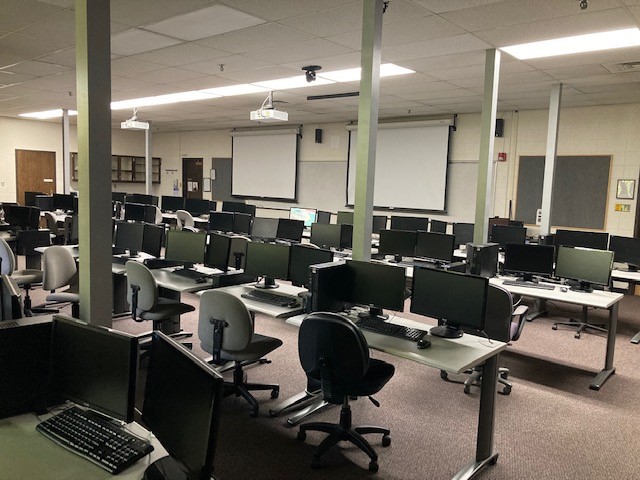

Figure 2:M&SE CAD/CAM Lab, ET 126, Fall 2021.

As the processing power and memory capacity of PCs continued to improve and the cost eventually dropped, the high-end CAD/CAM software that once only ran on mainframe computers or on high-end workstations became available on PCs. Then in the mid-90s, SolidWorks 95 was released as the first CAD/CAM system to run under MS Windows. Eventually, Catia and IDEAS also became available to run efficiently on Windows. Though these high-end CAD/CAM systems do have capability in the CAM area, most of the focus from these companies have been in the computer-aided engineering and computer-aided design arenas. WSU has, for the most part, continued to use other software for the CAM related courses. Currently, we are using FeatureCAM that allows the use of a neutral file format, such as STEP or IGES, from the CAD systems to generate toolpath geometry and G-codes to run the CNC machines.

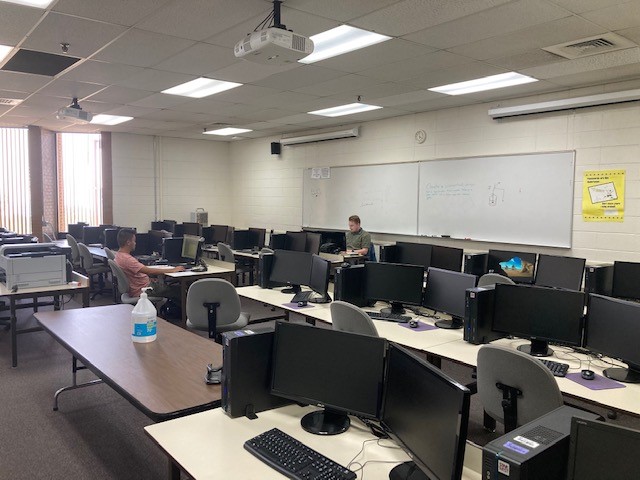

Figure 3:M&SE CAD/CAM Lab, ET 202, Fall 2021

As of the Fall Semester 2021, the Manufacturing & Systems Engineering Department has three main computer labs and a smaller lab in the CNC shop and the automation lab; all networked with high-speed Internet and local file servers. The three main computer labs contain a total of 87 PCs (MS Windows 10, Intel i7s or higher), with a number of CAD/CAM/CAE software products installed, including: SolidWorks 2021, AutoCAD, Inventor, Creo V8, Catia, FeatureCAM and Ansys. In the CNC lab, we also have 14 dedicated CAM workstations with FeatureCAM. The automation lab has the Fanuc programming software. Students also have free access to many of these programs in a student version they can download and use on their own computer at home.

When students complain now about lab resources don’t be surprised if some of the older faculty, who have been around since the early days, stare off in bewilderment and amazement.

Figure 4:M&SE CAM CNC Lab, ET 203, Fall 2021

Foreign Exchange

Our department has not had a formal foreign exchange program though we have had, over the years, students from Iran, Saudi Arabia, Vietnam, South Africa, Taiwan, and probably other countries. Many of these students have had significant challenges in the classroom because of the language barrier. Sometimes the challenges arise because of the cultural differences. Faculty need to be sensitive to the language and cultural differences and accommodate, as best they can, students from a variety of backgrounds. The expectations we place on students can be overwhelming in our attempt to best prepare them for success in their careers.

We all expect students to be completely honest and meet the expectations in our school’s honor code. Each course syllabus reminds students of this expectation and is reviewed at the start of each class. It would be well to remember that we are all human and we all make mistakes. We should use those mistakes as learning experiences and not stumbling blocks for students’ success.

In one of my classes, I suspected a few students were using the extended period to take the quizzes in the testing center to find ways to collaborate or cheat. I encourage students to collaborate on the homework but do their own work once they have discussed the problems. On quizzes however, they understand they are not to collaborate or discuss the quiz until it has been graded and handed back. It may be that a few students were taking turns by one of them taking the quiz early, recording the exam problems in their programmable calculator, and then sharing the information with the others in their small group. So, to alleviate the problem, I created multiple versions of the quiz for the next quiz. Upon grading the quiz, I found one student got the all the right answers for the other version of the quiz. In his file, I found that he had already been caught cheating in another class the previous school year and could be expelled from the university if he were caught cheating again. Being a foreign student, he would not only be expelled from the university, but would be sent home in disgrace by his embassy advisors.

I called the student into my office and showed him the reasons I knew he had cheated. I then asked for him to reveal who he collaborated with on the quiz. After some lengthy discussion, he finally revealed what he had done and who the other students were that had tried to help him in the quiz. I then showed him a copy of his file report documenting his previous honor code violation and the consequences of further violations. He then became defensive and very frightened realizing that he was now in jeopardy of being sent home when he was just a couple semesters away from graduation. We talked at length about the importance of being honest. I knew there was a chance that if I did not follow through with filling the report and potentially getting him expelled, that he may never learn his lesson. However, I also realized, that getting him expelled could also be devastating for him in his career pursuits and potentially many other aspects of his life. I then told him about my own efforts in life and the commitments that I had made in being honest and explained that it was a constant effort. And with that effort, habits are formed to make being honest part of who you are, a person of integrity. I explained to him that when he arrived at the end of his life, he didn’t want to look back and have regrets and sadness about being dishonest in life. I then asked him if he would make a commitment and promise to me that from this time forward that he would always be honest in his school work and in his career. He agreed and then committed to me in his broken English that he would always be honest and become a man of integrity. I then told him that I would not file a report but that I would just give him zero credit for the quiz but there would be many more quizzes where he could do well enough in the class to still get a good grade.

The student then stood up and walked around to my side of the desk where I became a little nervous not knowing what he might do. I stood up to meet him face to face thinking that maybe he just wanted to shake hands but also thought maybe he wanted to punch me in the face. He paused briefly, looking me straight in the eye, and then placed his hands on either side of my head, and pulled my head a little forward and planted a big slobbery kiss right in the middle of my forehead while saying, “I promise to be honest from this time forward.”

One year later the student came of my office after graduation and thanked me for helping him, not just with engineering mechanics, but with something that is much more important.

Stefan Giese – Student

Mr. Harward:

While taking an automation class that you taught several years ago, I behaved poorly in resolving frustrations regarding resource availability.

My behavior eventually became a serious discussion in your office…which is where I should have started the discussion.

Since graduation from WSU, I have earned my MBA from Penn State and recently finished training to become a Lean Manufacturing Six Sigma Black Belt (LSSBB). A few days ago, my manager asked me what part of my engineering degree, MBA, or 20 years’ experience in manufacturing had the greatest positive impact on the completion of my LSSBB and my ability to work well with others to complete complex projects. As I thought about his question, I came to the conclusion that the time you took to “put me back in my place” was the single experience that acted as the greatest catalyst for many of the important changes that I have made to improve myself, and how I interact with other people.

If I did not apologize for my behavior at the time of our confrontation, I do sincerely apologize for my past actions.

Thank you for the patience you showed several years ago, to teach me an important lesson that was not on the syllabus.

I have yet to program a robot since leaving WSU, but how well I deal with people every day has strong roots back to the discussion in your office.

Thanks again.

Stefan Giese

Project Manager

New Standard Corporation

74 Commerce Way

York, Pennsylvania 17406