3D Printing Adds Dimension to WSU Business Course

OGDEN, Utah – It’s no longer enough for Weber State University business students to just conceive new products. 3D printers have made it possible for students to design, produce and market products from start to finish.

Traditionally, the Information Systems & Technologies (IST) design course in the John B. Goddard School of Business & Economics requires students to develop websites and databases. Now, thanks to some new 3D printers, students develop a company idea, print a product prototype and then use the information systems to track sales and other data.

With the support of the dean of the business school, assistant professor Jeff Clements chose to use his research funds to purchase the first 3D printers for student exploration.

With the support of the dean of the business school, assistant professor Jeff Clements chose to use his research funds to purchase the first 3D printers for student exploration.

“3D Printing is an emerging technology that has the capability to change the face of the business environment in a way we haven’t seen since the industrial revolution,” Clements said. “Business students should know how this technology works.”

Clements spearheaded the implementation of rapid prototyping, a process of developing products quickly, and 3D printing to the IST program. The Goddard School is the first in Utah to include this emerging technology in business courses.

“We really want students to have the opportunity to do some interesting, cutting-edge things that help them understand not only the business environment today, but also what the business environment will look like in the future,” Clements said.

He added that students who have the chance to produce a prototype of their own making are motivated to embrace an entrepreneurial mindset, giving them a competitive advantage in the workforce.

“The course taught me that if I can think of it — I can create it,” said IST senior, Chris Heywood.

This semester, students are challenged to create a product to benefit recreational outdoor communities in Weber and Davis counties. They are encouraged to seek out needs of local businesses to craft a product.

Brandon Kasteler, IST senior, is developing a showerhead and adapter that connects to a water bottle for outdoor showers.

“Having been outdoors a lot, I recognize a shower is something I would use, and I think other people might be motivated to purchase one as well,” Kasteler said.

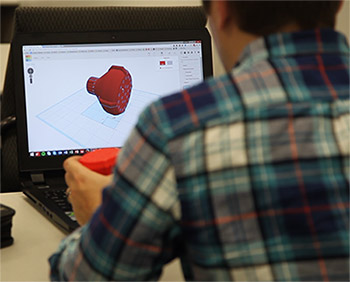

Once they have their ideas, students use modeling software to design products. The designs are then uploaded to the 3D printer and completed in a matter of minutes.

Rapid prototyping presents several challenges. For students using unfamiliar design software, the printed products don’t always turn out as they had imagined.

“If they aren’t careful, sometimes students find holes or gaps in their printed product or an accessory would be missing because it wasn’t quite attached in the design,” Clements said.

Students are encouraged to pay close attention to detail. They create several iterations of their prototype, improving the design until the final product.

This course, in its second semester, has already inspired collaboration. The Hall Global Entrepreneurship Program at WSU has contributed funds to purchase additional printers. The Goddard School now has a total of five 3D printers in use.

“The environment at Weber State is so supportive,” Clements said. “That support has helped me hone my desire to be creative and impact students.”

Visit weber.edu/wsutoday for more news about Weber State University.

For high-resolution photos, please visit the following links:

wsuucomm.smugmug.com/Press-Release-Photos/2016-photos/March-2016/i-Zzj8tZs/0/L/Brandon%20Still-L.png

wsuucomm.smugmug.com/Press-Release-Photos/2016-photos/March-2016/i-RH5TF6G/0/L/Prototype%20Still-L.png

wsuucomm.smugmug.com/Press-Release-Photos/2016-photos/March-2016/i-prdWJvb/0/L/Clements%20Still-L.png

Bailey Lefthand, Marketing & Communications

801-626-7948 • baileylefthand@weber.edu- Contact:

Jeff Clements, Assistant Professor of Information Systems & Technologies

801-626-6075 • jeffclements@weber.edu